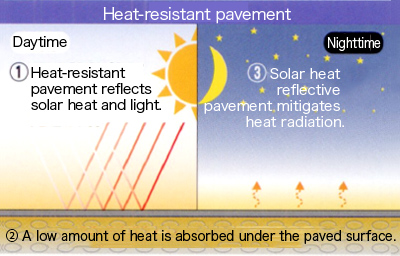

Infrared rays account for approximately 50% of solar energy. Solar heat reflective paints applied to a road surface reflect infrared rays, reducing the heat absorbed by, and the temperature of, the surface.

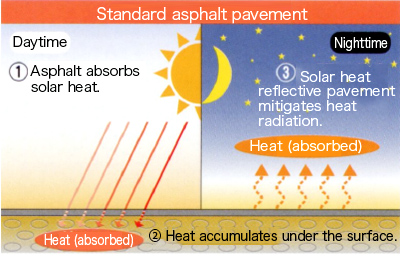

Generally, an asphalt pavement absorbs solar thermal energy during daytime hours and releases it as radiant heat at night. This mechanism causes the heat island problem. Solar heat reflective pavement is used as a method to reduce the amount of absorbed thermal energy. Tokyo is the city adopted this method the most, which in 2016, reached approximately 170,000 m2, of which Nippon Paint Industrial Coatings was involved in approximately 150,000 m2. Single-component water base paints are usable for parks and pools. Almost odorless urea paints are abrasion-resistant and usable even on heavy traffic roads such as those managed by the Tokyo Metropolitan Government. Our solar heat reflective paints can be applied widely from public facilities to streets in general residential areas.