Secure position with an overwhelmingly large domestic market share

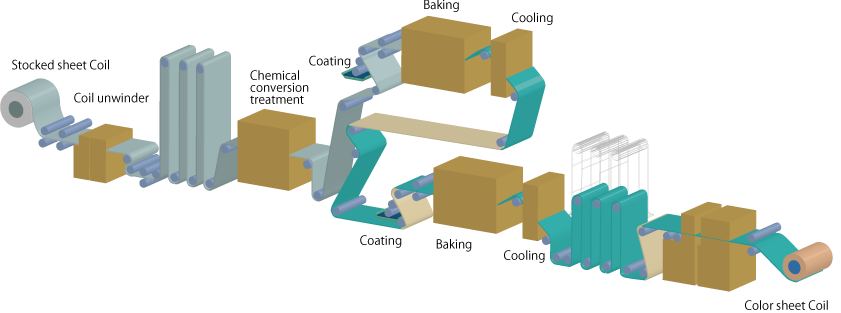

We enjoy a domestic market share of 70%, far ahead of others, in coil coatings due to our steady provision of dependable quality and ability to provide color consulting services. While offering improved basic paint film properties, such as weatherability, solvent resistance, workability, and adhesion, we provide products that boost productivity via a continuous coating process and minimize wasted coatings. Our coil coaintgs paint products are environmental friendly because solvents emitted from them are burned in an oven, emitting no VOCs into the atmosphere. Meanwhile, overseas markets have been increasingly booming in recent years. We are making active sales promotion efforts, especially in the Asian region. As our new market strategy, we have undertaken a project to achieve value-added technological innovation.